Video Overview

-

-

Mounting sensors typically involves welding or technicians trained in hydraulics. Attempting to perform these operations without proper training and knowledge can lead to injury or death. Please obtain professional installation services from trained technicians with welding and/or hydraulic certification.

-

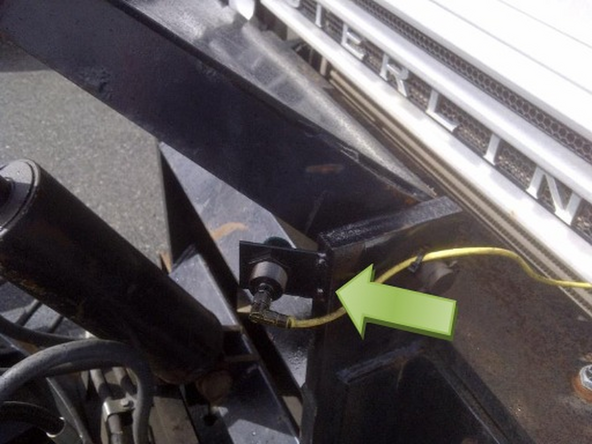

It is the client’s responsibility to provide direction and support to ensure that the sensors are mounted in optimal locations that do not interfere with normal maintenance and operation. It is advisable to always mount proximity sensors perpendicular to the moving equipment so that the sensor does not get impacted or damaged.

-

Sensors should always be configured to be active when the equipment is being operated. An example would be active when the plow is down, or when the manual spreader is actively applying material. This configuration helps reduce telemetry errors and maintains uniformity in winter operations reports.

-

-

-

Depending on the make and model, a proximity sensor will draw ~200 mA when activated. For this reason, all sensors must be powered from an ignition source. Preventing battery drain is a constant and necessary concern.

-

The IOX-WRKS provides a +12V (max 650mA) and ground source for powering sensors, when the vehicle is running. To use this feature, it requires activation at the time of configuration. Do not connect these wires (from the IOX-WRKS) to vehicle power or ground.

-

Brown - Ignition

-

Blue - Ground

-

Black - Signal Out

-

-

-

Winter vehicles operate in a highly corrosive environment. Use the following guidelines to reduce corrosion.

-

All in-cab wiring connections should be soldered and protected with heat shrink or tape. All external wiring connections must be soldered and weather-proofed using heat shrink or self-fusing tape. Dielectric grease must be applied to all proximity sensor connectors, both internally and externally.

-

-

-

The sensor should read ON when the plow is down.

-

-

-

The sensor should read ON when the wing is down. Please take into account wing position variability, and wing bounce while in operation.

-

-

-

The sensor should read ON when the arm is down.

-

-

-

The sensor should read ON when the blade is down.

-

-

-

Custom sensor brackets and flags are often required on the variety of vehicles used for sidewalk operations. The sensor should read ON when the lift arm/blade/blower/broom is down.

-